Today we are able to manufacture the entire range of seals, as we have a completely integrated Production facility, to produce Seals up to 3500 millimetres in a single tool in Metal Rubber, Fabric Rubber, Polyurethane and Nylon materials.

Complete range of Raw rubbers and Chemicals in stock.

Fresh compounds made for production for all Compounds

We manufacture our own moulds for the large size non-standard seals up to 3500 millimetres of any profile with Cad Cam & CNC machinery.

We produce 70 new moulds per day, out of 250 job cards sent daily to production. We design our Tools on Master CAM programme which directly feeds the CNC machines with the complete computer programme to have the mould made as per the desired design. Our Strength is to be able to make the mould designs very quickly and get the moulds approved immediately.

Our vertical machining centre being a 3 axis machine, is used for making moulds with complex shapes.

4 VMC, Vertical Machining Centers

13 CNC Lathe machines up to 700mm

70 new moulds made daily

Our vertical turning lathe with its high speed can turn and make big moulds very quickly.

We cut and fabricate the metal ourselves for our moulds, to be quick with our production, giving us the complete flexibility and be able to provide timely deliveries of our seals for our customers.

Raw metal stock for Moulds

Raw metal stock for Moulds

We produce Seals up to 3500 millimetres in single tool in all materials like metal to rubber, fabric rubber, polyurethane and nylons.

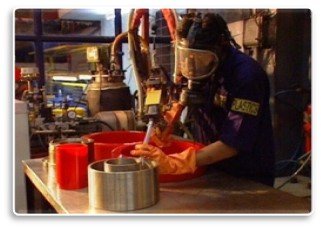

Our largest Injection Moulding machine can produce Seals up to 550 millimetres in polyurethane, Larger than that we produce by a casting process up to 3500 millimetres.

We are equipped with Large size presses ranging from 1 meter up to 2.5 meters. Alternately we can also produce complexed larger size seals by Step Moulding process.

2500 mm Moulding Press

PU & Nylon Casting Equipment